Adsorption Pressure Parameters for PSA Nitrogen & Oxygen Generation Systems

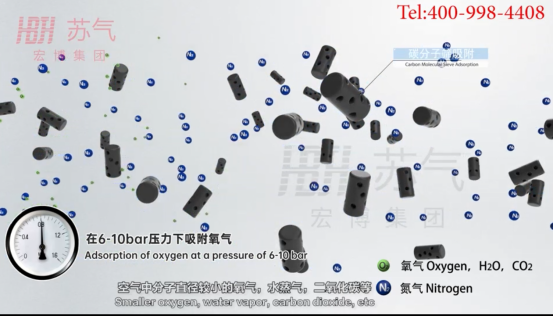

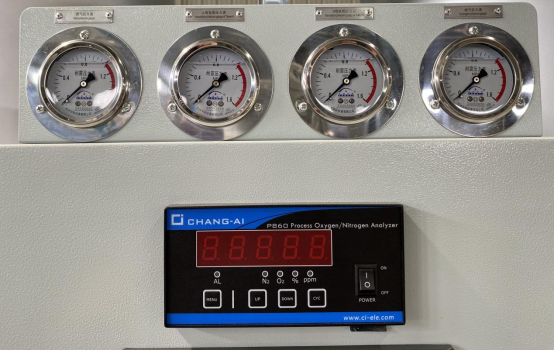

In pressure swing adsorption (PSA) air separation systems, the standard adsorption pressures are:

- PSA oxygen generators: Typically operate at 5.5 bar using zeolite molecular sieves

- PSA nitrogen generators: Normally function at 7-8 bar with carbon molecular sieves (CMS)

These optimized pressure ranges ensure:

• Maximum adsorption efficiency for each molecular sieve type

• Ideal thermodynamic working conditions

• Balanced energy consumption and production output

Consequences of Excessive Adsorption Pressure (>8 bar for N; >5.5 bar for O₂):

1. Energy inefficiency:

- Requires higher compression energy input

- Increases specific power consumption (kWh/Nm³)

2. Mechanical stress:

- Accelerated wear on adsorption vessel internals

- Reduced pressure vessel fatigue life

3. Adsorbent degradation:

- CMS pore structure collapse/zeolite crystal damage

- Shortened adsorbent service life (<3 years vs standard 5-8 years)

4. Process instability:

- Non-uniform gas flow distribution

- Product purity fluctuations (±0.5-2% variance)

5. Safety risks:

- Increased leakage potential at flange connections

- Higher explosion hazard in oxygen systems

*Note: All pressure values refer to gauge pressure (barg) at 20°C ambient conditions. Actual operating parameters may vary ±0.3 bar based on specific sieve specifications and plant design.