ASME Heat Exchanger Types/Design Manufacturer

Product Details

● As a certified manufacturer, we specialize in the engineering and fabrication of ASME Code heat exchangers, guaranteeing the highest standards of safety, quality, and regulatory compliance. Our expertise covers the full spectrum of types, including efficient Plate (PHE), robust Shell and Tube, and custom air-cooled designs. We focus on performance-driven features: superior thermal efficiency to reduce operational costs, corrosion-resistant materials for longevity, and designs optimized for easy maintenance to minimize downtime. Every unit is custom-engineered to your specific pressure, temperature, and duty requirements, ensuring reliable performance in the most demanding industrial applications, from chemical processing to power generation. |  |

Technical Parameters

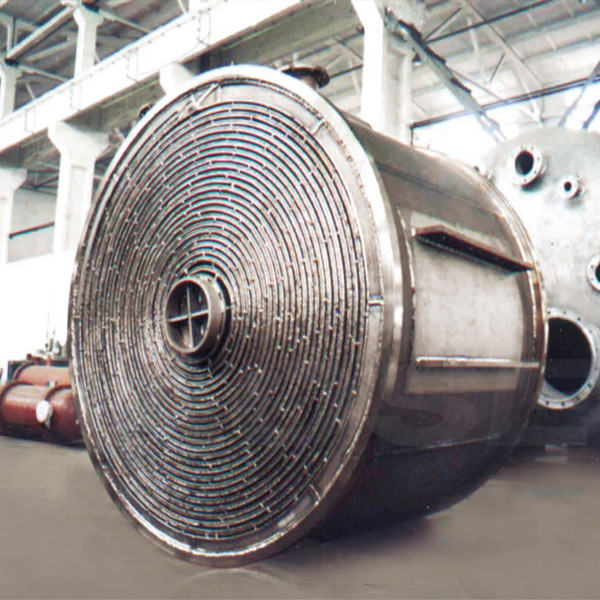

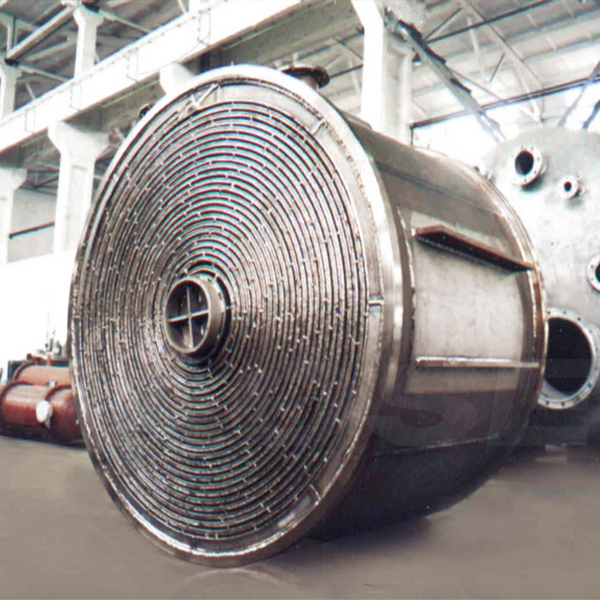

| Name | Spiral Plate Heat Exchanger | Applied Field | Salt Chemical,Coal Chemical,Chemical Fertilizer,Pesticide,Petrochemical,Synthetic Resin & Plastics,Rubber,Chemical Fiber,Pharmaceutical Chemical,Daily Chemical,Chemical Additives,Coatings & Dyes,Agricultural Products Chemical,Fermentation,Biochemical,Marine Chemical Industry etc. |

| Area | 0~1000m² | ||

| Temperature | -196~1000℃ | ||

| Pressure | -0.1~3MPa | ||

| Products | Various | Code & Standard | GB,ASME,TEMA,PED,DIN,AS,JIS,MOM,DOSH etc. |

| Materials | C.S.,S.S.,Clad Plate,Special Materials(Including Ti,Cu,Al,Zr,Nickel, Hastelloy,Monel,Inconel etc.) | Tube Type | Spiral Plate |

| Tube Bundle Type | Fixed | ||

| Grade | Industry |