Containerized PSA Oxygen Generator for Cylinder Filling in Oxygen Plant

Bottled oxygen is gradually replaced by the oxygen produced by the oxygen generator due to the trouble of changing bottles and high cost. Jiangsu tai oxygen launched the filling and filling oxygen generator, which automatically fills and fills bottles with a full set of processes, with high oxygen purity, low cost and fast investment recovery.

Product Advantages

● The filling and bottle filling oxygen generator is more and more accepted by customers. It is safe and simple to operate, saves the trouble of manual bottle replacement, operates at full load for 24 hours, has fast investment recovery, low equipment noise and long service life. |

|

Provide clean raw air for the oxygen generator through the air purification component, ensure the adsorption efficiency and service life of molecular sieve.

The air storage tank assembly ensures the stable gas consumption of the system.

Oxygen buffer tank ensures stable gas supply to the system.

International famous brand valves (Burkert, Gumu, Germany) are selected, Japan (SMC, CKD, etc.) is a reliable guarantee for the stable operation of PSA equipment.

The unique pressing technology is a reliable guarantee for the service life of molecular sieve.

The pressing force is constant and does not change with the change of stroke.

The cylinder is equipped with indicator rod,which can directly measure the stroke.

With sinking alarm and limit shut down function.

The gas required by the cylinder is directly taken from the adsorption tower, which can work synchronously with the adsorption tower at any time.

Testing process in strict accordance with standards, ensure that each equipment leavingthe factory is safe, reliable and stable.

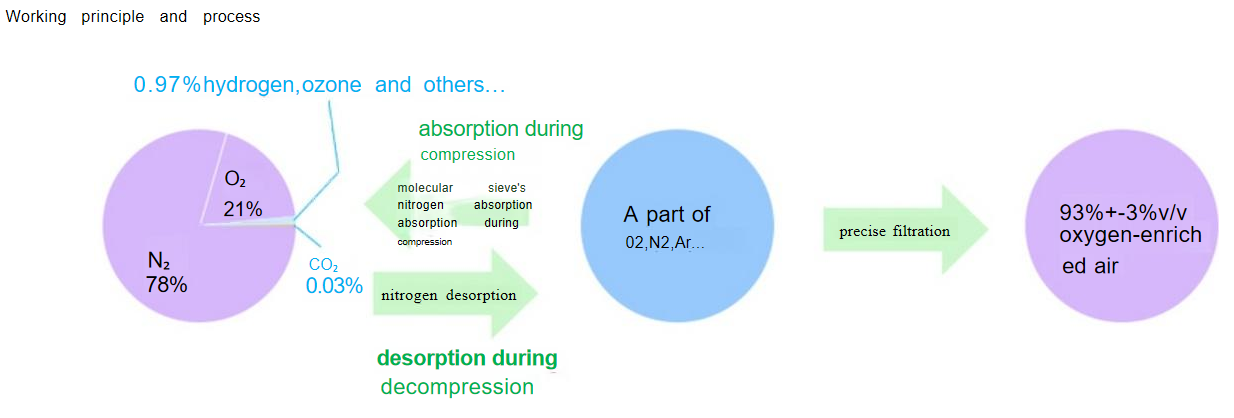

Oxygen generator diagram