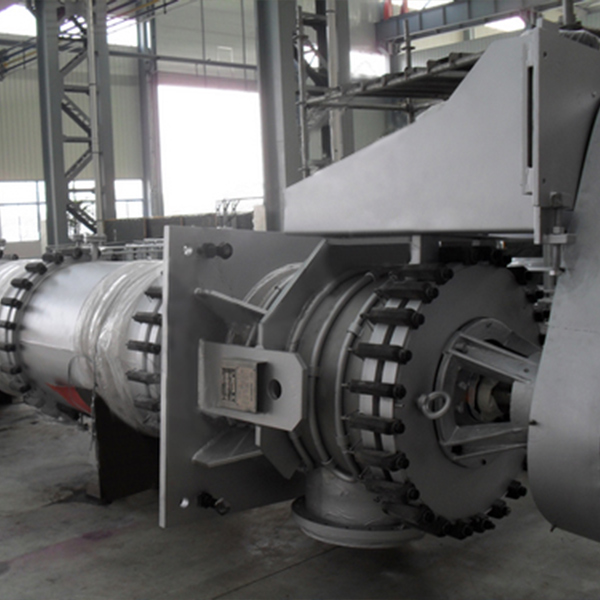

Industrial Wastewater Evaporator/Solvent Recovery System/Scraped Surface Evaporator

Product Details

● Industrial Wastewater Evaporators reduce liquid waste volume by boiling off water, significantly cutting disposal costs and enabling reuse. Solvent Recovery Systems typically use distillation within evaporators to purify and reclaim valuable solvents from waste streams, reducing procurement costs and environmental impact. ● The Scraped Surface Evaporator is a key technology for both, designed to handle viscous, fouling, or crystallizing materials. A rotating scraper continuously wipes the heated surface, maintaining high heat transfer efficiency and preventing scale buildup. ● These systems are critical in chemical processing, pharmaceuticals, metal finishing, and paint manufacturing for waste minimization, regulatory compliance, and resource recovery. |  |

Technical Parameters

| Name | Scraper Film Evaporator | Applied Field | Salt Chemical,Coal Chemical,Chemical Fertilizer,Pesticide,Petrochemical,Synthetic Resin & Plastics,Rubber,Chemical Fiber,Pharmaceutical Chemical,Daily Chemical,Chemical Additives,Coatings & Dyes,Agricultural Products Chemical,Fermentation,Biochemical,Marine Chemical Industry etc. |

| Evaporation Area | 0.8~50m² | ||

| Temperature | 0~250℃ | ||

| Vacuum | 70KPa | ||

| Capacity | 160~5000kg/h | Code & Standard | GB,ASME,TEMA,PED,DIN,AS,JIS,MOM,DOSH etc. |

| Materials | C.S.,S.S.,Lining,Clad Plate,Special Materials(Including Ti,Cu,Al,Zr,Nickel, Hastelloy,Monel,Inconel etc.) | Motor Power | 1.1~45KW |

| Heating Medium | Steam,Heat Conduction Oil | ||

| Structure Type | Scraper |