Ammonia Cracking Hydrogen Generator for On-site Industrial Hydrogen Production

Products principle introduction

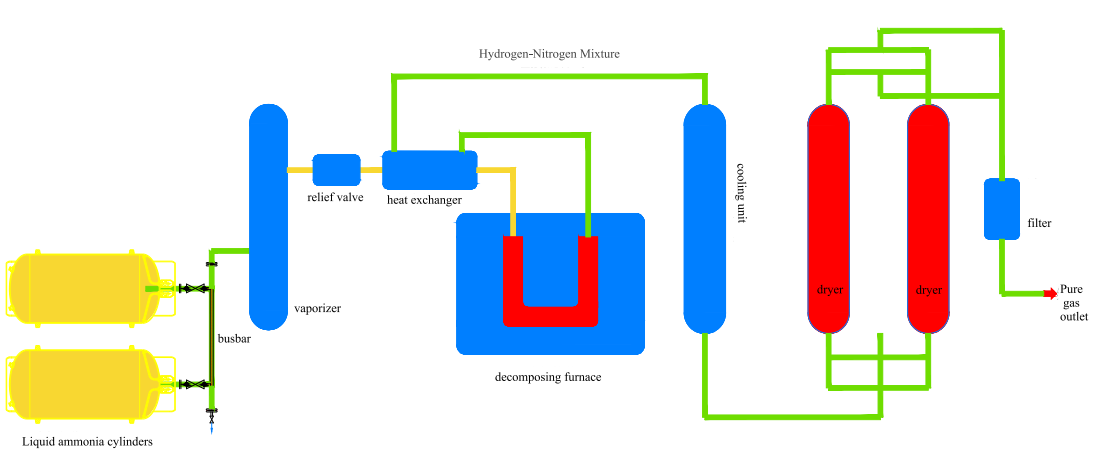

Ammonia decomposition for hydrogen production is a proces s in which liquid ammonia is used as raw material and heated at 800 ℃ -850 ℃ under the action of nick el catalyst to decompose into a hydrogen nitrogen mixture gas containing 75% hydrogen and 25% nitro gen. The decomposition rate can reach 99.9%. The dew point is -10 ℃. Through the HBFC series gas p urification device generated by our company, high-purity gas with a dew point of -60 ℃, residual ammo nia content of 5ppm, and residual oxygen content of 5ppm can be obtained.

chemical equation:2NH3=3H2+N2-22080 calorie.

Characteristics of ammonia decomposition

● Low equipment investment: The process is mature and simple, with a short flow and low price. It still has high economy for extracting pure hydrogen. ● Low operating cost: Liquid ammoni a raw materials are inexpensive, with low energy consumption and high efficiency, making it the most economical source of protective atmosphere. ● Reli able performance and long service life: High-quality catalysts, heat-resistant stainless steel inner tanks, nickel-chromium alloy electric heating elements and stainless steel valves ensure the service life of the entire system. ● Simple installation: Skid-mounted structure, small in size, compact in structure, no infrastructure is required. Just connect water, electricity and air inlet and out let pipes, and it can be put into normal production. |  |

Technical parameter

| Decomposition without purified ammonia | ||||||||

| Model | (Nm³/h)Gas production | (kg/h) Ammonia consumption | VHz electric source | KW ammon -ia dissociati -on power | Heating element | (DNmm) Inlet pipe size | (DNmm) Outlet pipe diameter | L*W*H (mm) Host |

| HBAQ-5 | 5 | 2.00 | 220;50 | 6.0 | Resistor Flat Strip | DN6 | DN6 | 1150*770*1750 |

| HBAQ-10 | 10 | 4.00 | 380;50 | 12.0 | Resistor Flat Strip | DN10 | DN15 | 1340*940*1750 |

| HBAQ-20 | 20 | 8.00 | 380;50 | 24.0 | Resistor Flat Strip | DN15 | DN20 | 1420*1500*1800 |

| HBAQ-30 | 30 | 12.00 | 380;50 | 36.0 | Resistor Flat Strip | DN15 | DN25 | 1420*1500*1800 |

| HBAQ-40 | 40 | 16.00 | 380;50 | 48.0 | Coiled Flat Strip | DN20 | DN32 | Ø1800*2000 |

| HBAQ-50 | 50 | 20.00 | 380;50 | 60.0 | Coiled Flat Strip | DN25 | DN40 | Ø1800*2000 |

| HBAQ-60 | 60 | 24.00 | 380;50 | 70.0 | Coiled Flat Strip | DN25 | DN40 | Ø1800*2000 |

| HBAQ-80 | 80 | 32.00 | 380;50 | 90.0 | Coiled Flat Strip | DN25 | DN40 | 01800*2240 |

| HBAQ-100 | 100 | 40.00 | 380;50 | 110.0 | Coiled Flat Strip | DN25 | DN40 | Ø1800*2345 |

| HBAQ-120 | 120 | 48.00 | 380;50 | 120.0 | Coiled Flat Strip | DN40 | DN50 | Ø1850*2200 |

| HBAQ-150 | 150 | 60.00 | 380;50 | 150.0 | Coiled Flat Strip | DN40 | DN50 | Ø1840*2430 |

| HBAQ-180 | 180 | 72.00 | 380;50 | 180.0 | Coiled Flat Strip | DN40 | DN50 | 02040*2600 |

| HBAQ-200 | 200 | 80.00 | 380;50 | 200.0 | Coiled Flat Strip | DN50 | DN65 | Ø1940*2670 |

| HBAQ-250 | 250 | 100.00 | 380;50 | 250.0 | Coiled Flat Strip | DN65 | DN80 | Ø1940*2750 |

| HBAQ-300 | 300 | 120.00 | 380;50 | 300.0 | Coiled Flat Strip | DN65 | DN80 | 02210*2750 |

| Decomposition with purified ammonia | |||||||||

| Model | (Nm³/h)Gas production | (kg/h) ammonia consumption | VHz electric source | KW ammon -ia dissociati -on power | KW drying power | heating element | (DNmm) Inlet pipe size | (DNmm) Outlet pipe diameter | L*W*H (mm) Host |

| HBAQFC-5 | 5 | 2.00 | 220;50 | 6.00 | 1.00 | Resistor Flat Strip | DN6 | DN6 | 1500*890*1700 |

| HBAQFC-10 | 10 | 4.00 | 380;50 | 12.00 | 1.20 | Resistor Flat Strip | DN10 | DN15 | 1520*940*1800 |

| HBAQFC-20 | 20 | 8.00 | 380;50 | 24.00 | 3.60 | Resistor Flat Strip | DN15 | DN20 | 1800*1420*1620 |

| HBAQFC-30 | 30 | 12.00 | 380;50 | 36.00 | 4.50 | Resistor Flat Strip | DN15 | DN25 | 1800*1420*1620 |

| HBAQFC-40 | 40 | 16.00 | 380;50 | 48.00 | 3.60 | Coiled Flat Strip | DN20 | DN32 | 2200*950*2200/01800*2000 |

| HBAQFC-50 | 50 | 20.00 | 380;50 | 60.00 | 4.50 | Coiled Flat Strip | DN25 | DN40 | 2250*950*2500/O1800*2000 |

| HBAQFC-60 | 60 | 24.00 | 380;50 | 70.00 | 4.50 | Coiled Flat Strip | DN25 | DN40 | 2250*950*2500/Q1800*2000 |

| HBAQFC-80 | 80 | 32.00 | 380;50 | 90.00 | 9.00 | Coiled Flat Strip | DN25 | DN40 | 2300*1000*2600/O1800*2240 |

| HBAQFC-100 | 100 | 40.00 | 380;50 | 110.00 | 9.00 | Coiled Flat Strip | DN25 | DN40 | 2350*1100*2600/O1800*2345 |

| HBAQFC-120 | 120 | 48.00 | 380;50 | 120.00 | 9.00 | Coiled Flat Strip | DN40 | DN50 | 2350*1200*2100/O1850*2200 |

| HBAQFC-150 | 150 | 60.00 | 380;50 | 150.00 | 12.00 | Coiled Flat Strip | DN40 | DN50 | 2350*1500*3000/O1840*2430 |

| HBAQFC-180 | 180 | 72.00 | 380;50 | 180.00 | 12.00 | Coiled Flat Strip | DN40 | DN50 | 2350*1500*3000/02040*2600 |

| HBAQFC-200 | 200 | 80.0 | 380;50 | 200.0 | 15.0 | Coiled Flat Strip | DN50 | DN65 | 2350*1500*3000/O1940*2670 |

| HBAQFC-250 | 250 | 100.0 | 380;50 | 250.0 | 15.0 | Coiled Flat Strip | DN65 | DN80 | 2850*1700*3000/O1940*2750 |

| HBAQFC-300 | 300 | 120.0 | 380;50 | 300.0 | 18.0 | Coiled Flat Strip | DN65 | DN80 | 2850*1700*3000/02210*2750 |

Process Flow Diagram of Ammonia Decomposition for Hydrogen Production