Hot Sale 99.999% Purity Hydrogen Production Device of Methanol Cracker H2

CJDL-I serise machine

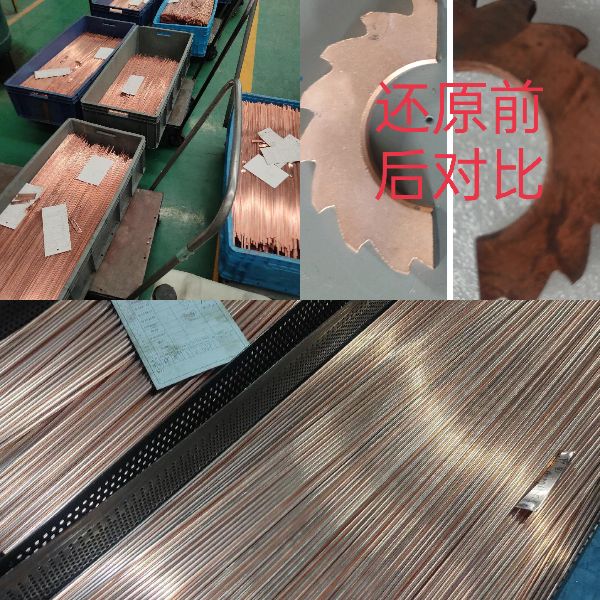

● CJDL-I serise machine reducing gas mixture produced enters the furnace chamber and reacts chemically with the small amount of oxygen brought in by the workpieces and the oxidized surface of the workpieces at high temperatures. The reaction products are H2O and CO2. This oxidative atmosphere is displaced from the furnace chamber as more cracking gas mixture enters, ultimately achieving chemical equilibrium within the furnace atmosphere, thus realizing the purpose of atmosphere protection. |  |

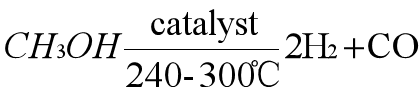

CH3OH Cracking reaction equation

| For example, the low-temperature cracking reaction equation of 99.9% industrial methanol is: |  |

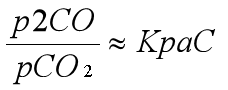

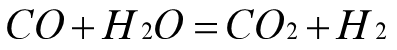

Water gas equilibrium reaction equation

Cracking gas composition

At 900°C, the composition of the cracking gas and furnace gas when using 99.9% methanol as raw material is as follows(Tube furnace):

| Category | Gas composition (%) | |||

| H2 | CO | CO2 | CH4 | |

| cracked gas | 66 | 33 | 0.5 | 0.2 |

| furnace gas | 66.5 | 32 | 0.2 | 0.2 |

CJDL-I serise Methanol low-temperature cracking machine

The process of atmosphere protection in metal heat treatment involves continuous cycles of oxidation and reduction reactions. The ultimate goal of atmosphere protection is to maintain a balance between oxidation and reduction reactions within the furnace. Typically, people adjust the protective atmosphere appropriately to meet the heat treatment requirements of different metal materials. However, the protective atmosphere for heat treatment should generally satisfy: