High Purity Methanol Cracker Hydrogen H2 Plant Production Device

High-temperature pyrolysis

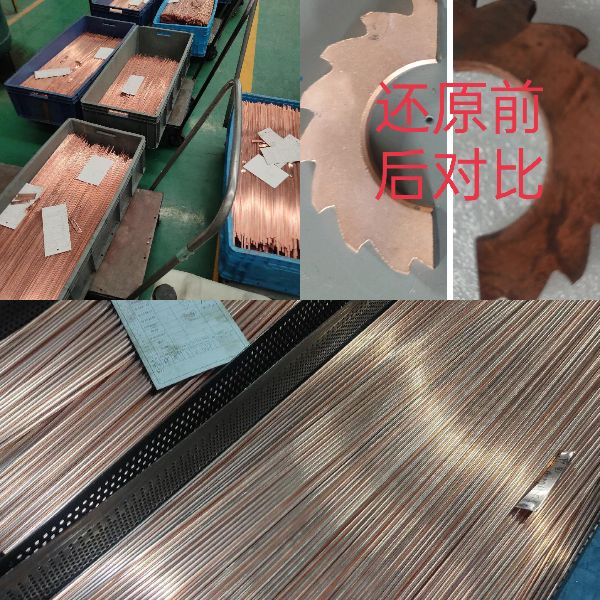

● Currently, most heat treatment processes in China still use dripping atmosphere, where methanol is dripped into the furnace and decomposes at high temperatures. A smaller number of factories use external high-temperature cracking equipment for this purpose. ● Methanol decomposes spontaneously at high temperatures of 930°C, absorbing a large amount of furnace heat and causing temperature fluctuations in the furnace body. Additionally, it forms carbon black that clogs the dripping outlet, and the surface of the workpiece is prone to developing spots. ● The high-temperature pyrolysis equipment performs pyrolysis outside the furnace, consuming energy equivalent to that of dripping pyrolysis inside the furnace. The resulting carbon black clogs the internal pipelines, requiring cleaning every 2-3 days on average. Significant energy consumption also occurs during startup and shutdown. |  |

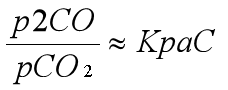

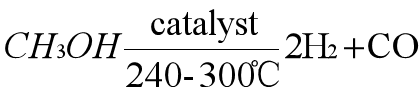

CH3OH Cracking reaction equation

| For example, the low-temperature cracking reaction equation of 99.9% industrial methanol is: |  |

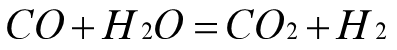

Water gas equilibrium reaction equation

Cracking gas composition

At 900°C, the composition of the cracking gas and furnace gas when using 99.9% methanol as raw material is as follows(Tube furnace):

| Category | Gas composition (%) | |||

| H2 | CO | CO2 | CH4 | |

| cracked gas | 66 | 33 | 0.5 | 0.2 |

| furnace gas | 66.5 | 32 | 0.2 | 0.2 |

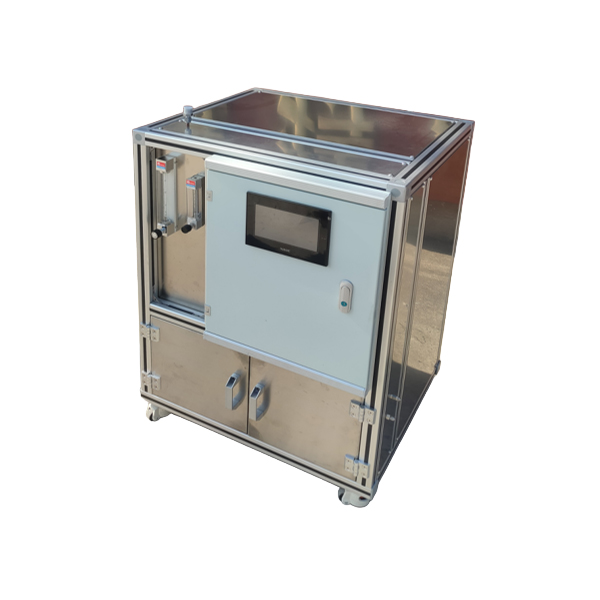

CJDL-I serise Methanol low-temperature cracking machine

The process of atmosphere protection in metal heat treatment involves continuous cycles of oxidation and reduction reactions. The ultimate goal of atmosphere protection is to maintain a balance between oxidation and reduction reactions within the furnace. Typically, people adjust the protective atmosphere appropriately to meet the heat treatment requirements of different metal materials. However, the protective atmosphere for heat treatment should generally satisfy: