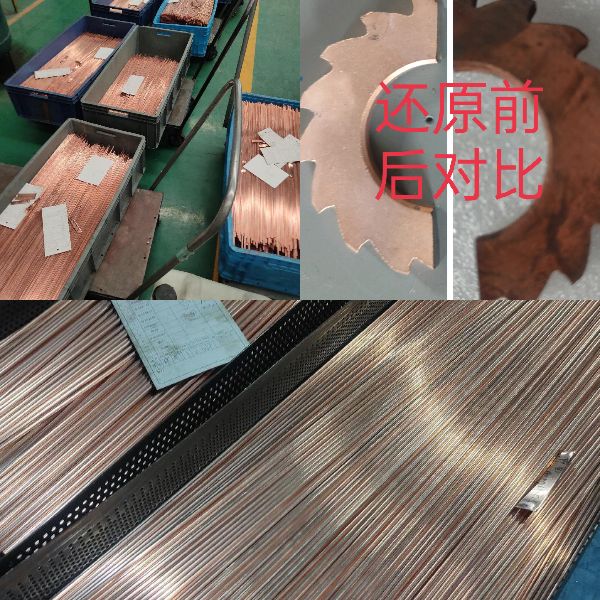

Hydrogen Gas Plant Methanol cracking for hydrogen production generator

CJDL-I serise Methanol low-temperature cracking machine

● CJDL-I serise machine is a thermal treatment protective atmosphere generator jointly developed by our company and the Applied Chemistry Research Institute of North University under the direct jurisdiction of the Ministry of National Defense. How it works of the CJDL-I serise machine :First, vaporize the incoming methanol to a specific temperature range. ● The methanol vapor then comes into full contact with the catalyst in a low-temperature environment (260°C), where it decomposes to produce a reductive mixed gas primarily consisting of hydrogen and carbon monoxide. This mixed gas is then cooled using specialized condensation equipment based on its different components and dew point temperatures before entering the thermal treatment device. |  |

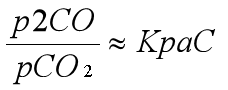

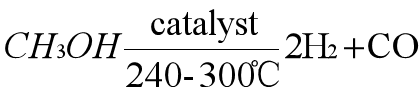

CH3OH Cracking reaction equation

| For example, the low-temperature cracking reaction equation of 99.9% industrial methanol is: |  |

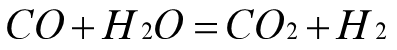

Water gas equilibrium reaction equation

Cracking gas composition

At 900°C, the composition of the cracking gas and furnace gas when using 99.9% methanol as raw material is as follows(Tube furnace):

| Category | Gas composition (%) | |||

| H2 | CO | CO2 | CH4 | |

| cracked gas | 66 | 33 | 0.5 | 0.2 |

| furnace gas | 66.5 | 32 | 0.2 | 0.2 |

CJDL-I serise Methanol low-temperature cracking machine

The process of atmosphere protection in metal heat treatment involves continuous cycles of oxidation and reduction reactions. The ultimate goal of atmosphere protection is to maintain a balance between oxidation and reduction reactions within the furnace. Typically, people adjust the protective atmosphere appropriately to meet the heat treatment requirements of different metal materials. However, the protective atmosphere for heat treatment should generally satisfy: